What is Root Cause Analysis (RCA)?

Root Cause Definition

Root Cause Analysis (RCA) is a set of analyzing and problem-solving techniques targeted at identifying the actual root cause or the reason for the nonconformity. The need for RCA stems from the fact that the elimination of the symptoms of the problems is not alone sufficient to address the problem, it has to be addressed at the source. If you solve a problem at this root level, it is highly probable that you can prevent its recurrence.

Root Cause Analysis (RCA) is a set of analyzing and problem-solving techniques targeted at identifying the actual root cause or the reason for the nonconformity. The need for RCA stems from the fact that the elimination of the symptoms of the problems is not alone sufficient to address the problem, it has to be addressed at the source. If you solve a problem at this root level, it is highly probable that you can prevent its recurrence.

The root cause is just what it sounds like: the “root” of the problem.

Here is an example:

A tennis court looks sloppy because weeds are growing in the cracks.

-

- Cutting the weeds only eliminates the symptom as it may grow back.

- Killing/removing the root will eliminate the problem.

If there is more than one root cause discovered after analysis, all the causes have to be addressed for corrective actions to be successful. A root cause analysis is considered successful when the problem does not recur.

- Filling the crack will prevent the problem from recurring.

The most common approach to solve problems is to rush and find an immediate action to solve the problem. This approach will not help in the long run as we are not taking any steps to understand the reason why the problem occurred or steps to prevent it from occurring again. A better approach would be to think beyond the obvious and find an effective way to eliminate the root cause that led to this problem. Various methods can be used to determine the true root cause, such as 5 whys or cause and effect diagrams.

Training

- Find Other Root Cause Training Courses

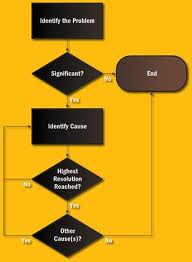

Steps in Root Cause Analysis

- Gather data

- Define the problem/non-conformance clearly

- Once a candidate for RCA (or the problem or the non-conformance) has been identified, gather sufficient information about it.

- Ask What, How and When about the problem and document it.

- Perform the analysis

- Use any of the root cause analysis tools & techniques for performing the analysis.

- Use your logic and choose the best possible way to solve the problem in a simple, effective, and least expensive method. Take care to eliminate the non-probable causes.

- Implement the solution

- Recommend and implement the best solution.

- Also take care to see that these corrective actions do not induce any other or related unforeseen problems. Check that the problem does not recur.

- Use the data from the learning and analysis of the RCA and use it in the continuous improvement projects.

Can we really eliminate the Root Cause?

There may be times that you may not be able to remove the root cause completely but, will most likely be able to prevent its recurrence or at the very least minimize the likelihood of recurrence.

Where is it useful?

RCA can be used in any field across any domain where the organization uses safety-based, production-based, process-based, failure-based, and software-based systems. What are the tools and techniques used in RCA?

The most common tools and techniques used in RCA are:

The most common tools and techniques used in RCA are:

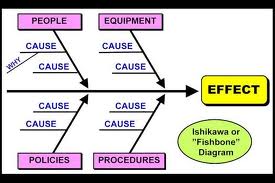

- Fishbone (Ishikawa) diagram – used during brain storming exercises when many possibilities of the resolution exist.

- Pareto chart – used to classify the problems based on the Pareto principle which says 80-% of the problems have 20% of the causes.

- Cause and Effects diagram – used to find the causes and effects of all possible causes of the problem

- 5 Whys – used to determine the root cause by repeatedly asking “why?”

Examples where RCA can be used or candidates for RCA:

- Resolution of customer complaints

- Addressing non-conformances from an external or internal audit

- Error/defects existing in a product