ISO 9001 Simplified: Apply ISO 9001 to Baking Cookies

Applying ISO 9001 to your business can seem overwhelming. the9000store wanted to simplify ISO 9001 for you by applying it to baking cookies.

How does ISO 9001 apply to a business? Let’s say you bake cookies…

Whether it’s chocolate chip, sugar cookie, or garbage flavored, your customers will ultimately decide if your cookie is good. The standard tries to get you to achieve consistent results and continually improve the process. Thus, if you can make a good cookie most of the time, this helps you make it all of the time. Controlling and improving processes will yield better results!

Let’s look at this common recipe for baking cookies and apply parts of the standard to it.

Ingredients:

- 2 1/4 cups all-purpose flour

- 1 teaspoon baking soda

- 1 teaspoon salt

- 1 cup (2 sticks) butter, softened

- 3/4 cup granulated sugar

- 3/4 cup packed brown sugar

- 1 teaspoon vanilla extract

- 2 large eggs

- 2 cups (12-oz. pkg.) Semi-Sweet Chocolate Morsels

PREHEAT oven to 375° F.

COMBINE flour, baking soda and salt in a small bowl.

BEAT butter, granulated sugar, brown sugar and vanilla extract in large mixer bowl until creamy.

Add eggs, one at a time, beating well after each addition.

Gradually beat in flour mixture.

Stir in morsels.

DROP by rounded tablespoon onto ungreased baking sheets.

BAKE for 9 to 11 minutes or until golden brown.

Cool on baking sheets for 2 minutes; remove to wire racks to cool completely.

ISO 9001 Simplified

Let’s break down the (oversimplified) process of baking cookies into clauses 4-6 of the requirements your organization must meet to become certified. ISO 9001 simplified may help make this goal more easily achievable for your organization.

Download the ISO 9001 Baking Cookies PDF:

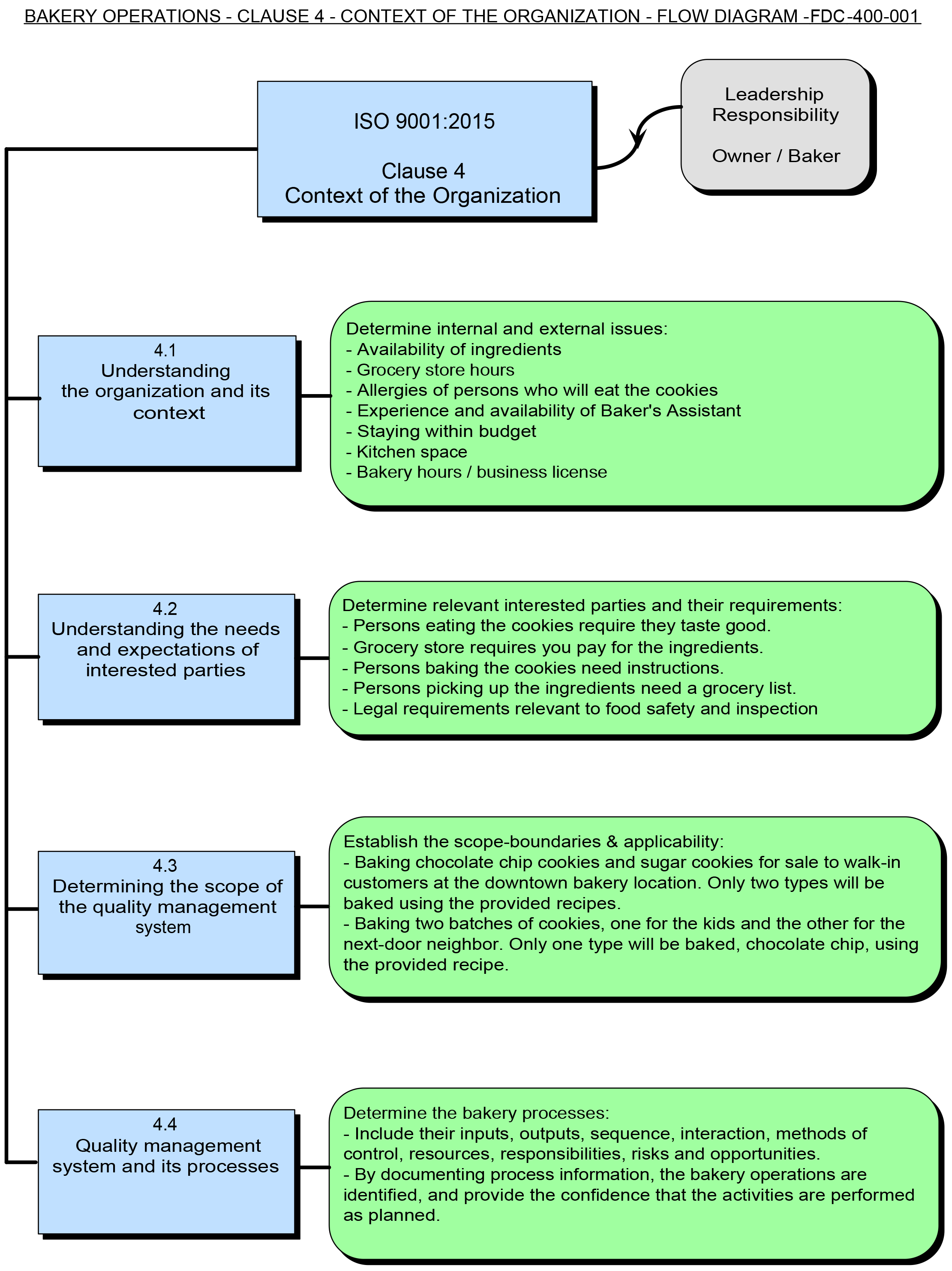

Section 4: Context of the organization

4.1 Determine internal and external issues:

- Availability of ingredients

- Grocery store hours

- Allergies of persons who will eat the cookies

- Experience and availability of Baker’s Assistant

- Staying within budget

- Kitchen space

- Bakery hours / Business license

4.2 Determine relevant interested parties and their requirements:

- Persons eating the cookies require they taste good.

- Grocery store requires you pay for the ingredients.

- Persons baking the cookies need instructions.

- Persons picking up the ingredients need a grocery list.

- Legal requirements relevant to food safety and inspection.

4.3 Establish the scope (boundaries and applicability):

- Baking chocolate chip cookies and sugar cookies for sale to walk-in customers at the downtown bakery location. Only two types will be baked using the provided recipes.

- Baking two batches of cookies, one for the kids and the other for the next-door neighbor. Only one type will be baked, chocolate chip, using the provided recipe.

- Note: Clause 8.3 does not apply as cookies are made following a recipe that someone else created.

4.4 Determine the bakery processes:

- Include their inputs, outputs, sequence, interaction, methods of control, resources, responsibilities, risks and opportunities.

- By documenting process information, such as in the table below, the bakery operations are identified, and provide the confidence that the activities are performed as planned.

- Note: Processes are different than your standard operating procedures (SOPs). Procedures are the documented process and should state what the required inputs, outputs, sequence, interaction and responsibilities are for that specific process. ISO 9001:2015 only requires you to have procedures if they are necessary to support your operations. Typically, a complex process or one that has a risk of producing inconsistent results should be documented. Documenting your processes also helps with training and preventing the loss of organizational knowledge.

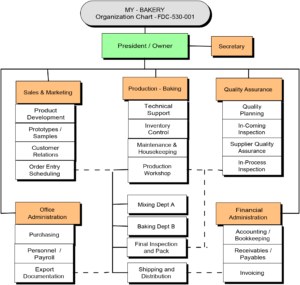

Section 5: Leadership

5.1 Leadership and commitment:

- The Owner / Baker will maintain focus on customer satisfaction and ensure the buyers are satisfied with the taste of the cookies.

- The Baker will take accountability for the entire cookie making process and ensure the kids and neighbors like the taste of the cookies.

- The Baker will invest in resources as needed to provide fresh cookies.

- The Baker will support the Assistant.

5.2 Establish a quality policy:

- The Baker will strive to make gooey and delicious cookies by continually improving the ingredients and baking process based on the feedback from the persons eating the cookies.

- The Baker will consider the strategic direction of the bakery when establishing the quality policy.

- The Baker will post a copy of the quality policy in prominent spots in the bakery for customers to see and in the kitchen as a reminder for the Baker and the Assistant.

5.3 Assign responsibility and authority:

- The Baker will make the cookies.

- The Assistant will buy the ingredients and assist the Baker.

- The Baker will look for opportunities to improve and will keep records on how the baking activities are going.

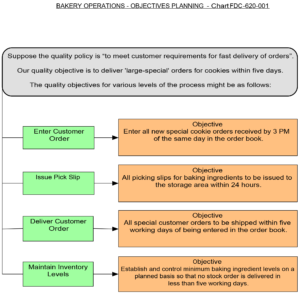

Section 6: Planning

6.1 Consider issues and requirements of interested parties and determine risks and opportunities:

- Risk of sickness if raw ingredients are not thoroughly baked.

- Risk of sickness if cookies are baked in unclean conditions (dirty kitchen and utensils).

- Risk the customers go elsewhere if they don’t like the cookies or if they are not ready in time.

- Opportunity to make the cookies smaller and have a larger quantity using the same amount of ingredients.

- Other risks and opportunities identified in table above.

- Plan and identify how the actions to address risks and opportunities can be integrated into the bakery operations.

6.2 Establish quality objectives and how to achieve them:

- Make consistently good cookies by following the recipe.

- Deliver on time.

- Make cookies gooier.

- Ensure the customers, the kids, and the neighbor are satisfied with the cookies.

- Ensure that large-special orders are delivered within five days.

6.3 When changes are made they need to be planned:

- Changes are carried out in a planned and organized way.

- To make cookies gooier, consider reducing the bake time.

- Before the bake time is changed, the cookies will be taste-tested to ensure they are cooked through.

Section 7: Support

7.1 Determine and provide resources:

- Is the Assistant trained on using the equipment (oven and mixer)?

- Is there a cooling rack to place the cookies on after they are baked?

- Is there ventilation in the kitchen in the event that the cookies burn?

- Is there a clean and effective display area in the bakery for the cookies?

- Is the temperature and humidity in the bakery such that the cookies remain fresh?

- Are the baking oven and the weigh-scale maintained and calibrated on a regular basis?

7.2 Ensure person’s doing work are competent:

- Does the Baker and Assistant have experience making cookies and/or can they follow a recipe?

- To maintain knowledge and remain competent, do the Baker and Assistant keep abreast of the latest recipes and industry techniques?

7.3 Ensure person’s doing work are aware of:

- The quality policy and the quality objectives.

- Consider posting printed copies the quality policy and objectives in the kitchen.

- The implications of not meeting requirements for the cookies.

- Their contribution in achieving the benefit of improved performance.

7.4 Determine internal and external communication:

- Who will tell the customers when the cookies are ready to eat?

- How will you tell the customers the cookies are ready?

- Who will bring the cookies to the customers?

7.5 Determine, create, update and control documented information:

- Documented information includes the recipe, grocery list, scope, quality policy, objectives and any documentation that supports the processes listed in the table above.

- The Baker updates everything as needed but will have to re-print and replace the old documents. The old documents have to be thrown away immediately, so they are not accidentally used.

- All documents are updated and controlled to ensure consistency.

- Documents are required to be available where and when they are needed.

Section 8: Operation

8.1 Plan and control operations.

Determine requirements and establish criteria for acceptance of processes and products:

- The cookies are required to taste good at time of delivery.

- Taste a cookie after each batch is baked to ensure the cookies taste good.

- If the date on the ingredients is past expiration, do not use.

- Keep the process above table up to date to give you confidence that the activities are being carried out as planned.

8.2 Communicate with customers, determine their requirements and review their requirements have been met before supplying product including when changes are made:

- Let the kids know when the cookies have cooled and are safe to eat.

- Notify the neighbor when bringing the cookies over to their house.

- The neighbors do not like visitors after 8pm.

- If the cookies aren’t done in time, let the neighbors know you will stop by the following day.

- Let the customers know their satisfaction is a priority with the bakery.

8.3 Establish, implement and maintain a design and development process:

- This clause is excluded from the scope since the cookies aren’t designed but follow a recipe another person created.

8.4 Control externally provided processes, products and services:

- Check the ingredients at the grocery store to ensure not expired before purchasing.

- Purchase efficiently (coupons?) to stay on budget.

- Keep grocery store receipts for one week.

- Seek out and make use of suppliers who have registered quality systems such as ISO 9001.

8.5 Production and service provision should be under controlled conditions:

- The oven must preheat before use.

- Ensure oven and all instruments are calibrated or verified according to specification.

- Any ingredients that state “refrigerate” must be stored in the refrigerator.

- Update the grocery list if replacing any ingredients or if requiring brand name items.

- Maintain records of production batches for first baked-first-out delivery.

- Identify and keep separate the chocolate chip cookies from the sugar cookies.

8.6 Verify requirements have been met before release:

- Taste-test the cookies before giving them to your customers.

- Keep records of quantities produced, by whom, and provided for use.

- Check temperature and humidity records so the cookies do not get stale or spoil.

- Check baking areas for clean and free of contamination conditions.

8.7 Ensure nonconforming outputs are controlled and identified:

- Burnt cookies get segregated from the good cookies and thrown in the trash once they’ve cooled.

- Ingredients from suppliers that do not meet the requirements are identified and returned to the supplier for replacement or corrective action.

Section 9: Performance evaluation

9.1 Determine what needs to be monitored and measured, what methods will be used and when you will analyze and evaluate the results:

- The bakery operations need to be monitored as they are performed. Check to see if the ingredient quantities are correct and if the oven temperature and bake time are as planned.

- The satisfaction of the kids and neighbors needs to be monitored. Ask them after they are eaten if they tasted good.

- The satisfaction of the walk-in customers needs to be monitored and measured. Ask them to take and complete a short survey form.

- The responses will be immediately analyzed and evaluated to determine if changes need to be made to a process or another recipe is to be used in the future.

9.2 Have an internal audit program:

- Have an objective and impartial person audit your processes and documentation to ensure the Bakery activities are effectively implemented and maintained.

- Have the results of the audit reported to the Owner / Baker and take prompt corrective action on shortcomings found.

9.3 Perform Management Reviews:

- During planned intervals, have Leadership (the Baker and Assistant), get together to review issues, performance, customer satisfaction, if quality objectives were met, audit results, external provider (grocery store) performance, if additional resources are needed and if there are opportunities for improvement.

Section 10: Improvement

10.1 Determine and select opportunities for improvement:

- How can you make the cookies better, more consistent, etc.?

- Look at each process for improvement opportunities.

- Look at improving the cookies as well as addressing future needs and expectations.

10.2 When a nonconformity occurs, react to it appropriately, determine and eliminate the cause and keep records:

- If the cookies burned, was the temperature to high? Were they left in the oven too long?

- Segregate the burnt cookies and throw away as soon as they have cooled.

- Make a new batch of cookies to replace the burnt ones.

- Document how many cookies burned, what was the cause and if a new batch was made to replace them.

- Retain this documentation for review and to track any trends in burnt cookies.

10.3 Continually Improve:

- Keep improving!

- Consider the results of analysis and evaluation and the outputs of management review as part of the continual improvement initiative.